More About Bullcaster Co.,ltd

Wiki Article

Things about Bullcaster Co.,ltd

Table of Contents5 Simple Techniques For Bullcaster Co.,ltdAn Unbiased View of Bullcaster Co.,ltd5 Easy Facts About Bullcaster Co.,ltd ExplainedThe Greatest Guide To Bullcaster Co.,ltdBullcaster Co.,ltd for Beginners

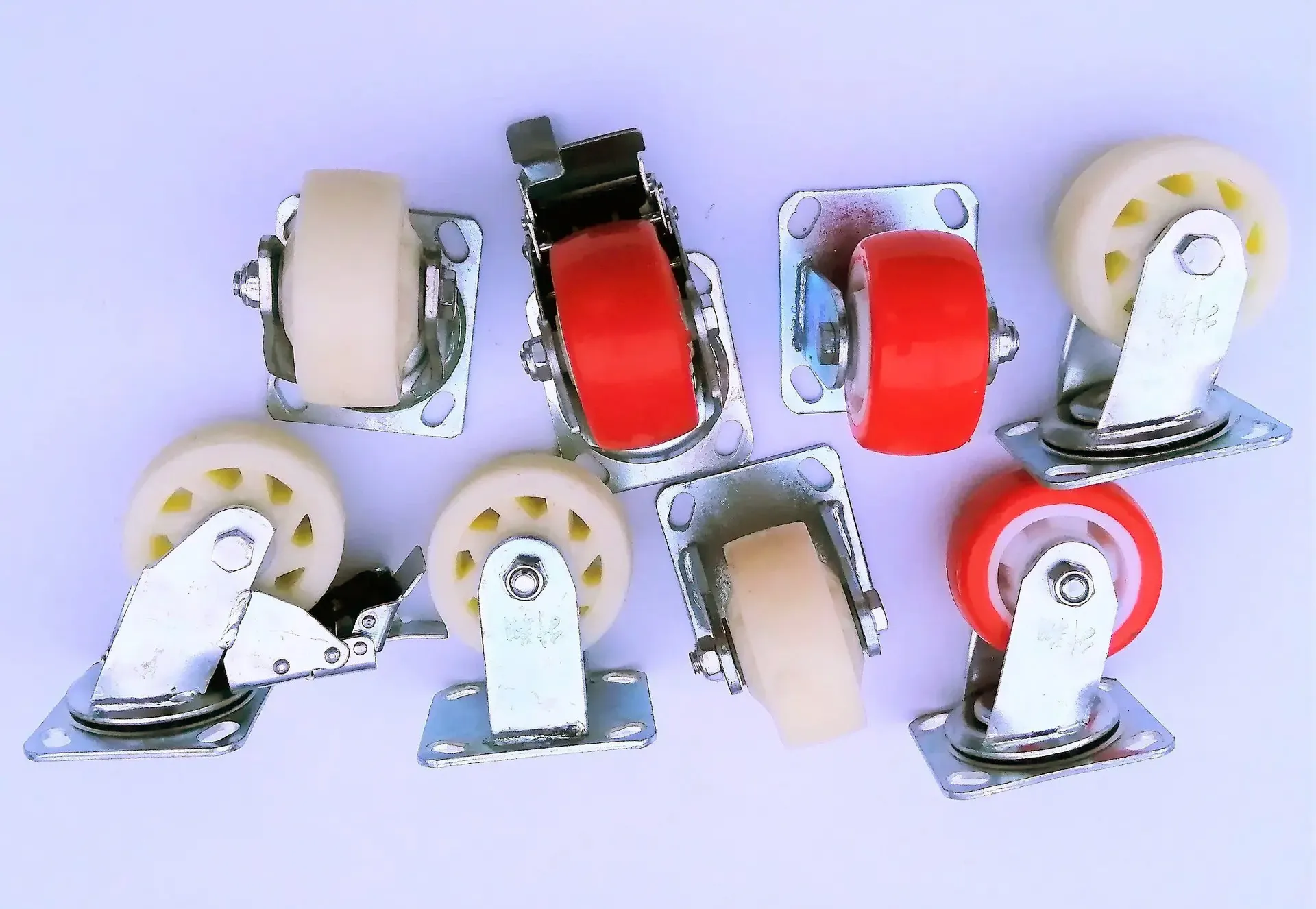

One of the most usual kind, plate wheels are characterized by a flat, square-shaped mounting surface area. They normally have four holes one on each edge of the placing surface which are made use of to protect home plate wheel to the item. They are called "plate casters" because the mounting surface area resembles as a square-squared plate (casters manufacturer).

If a workbench with casters is put on a sloped surface area, for instance, it may roll downhill unless the wheels are locked. Locking wheels supply the flexibility to secure the wheels in area, therefore protecting against the things on which they are placed from rolling or pivoting.

While plate wheels have level, square-shaped installing surface, stem wheels include a cylindrical-shaped rod for mounting. In the photo showed above, the wheel in the middle is a stem wheel.

Indicators on Bullcaster Co.,ltd You Need To Know

Hollow Kingpin casters are defined by a stemless style with a hole on the top of the placing surface area - heavy duty casters. To mount a hollow Kingpin caster, the caster is placed versus the things, after which a fastener like a screw or screw is driven via the opening as well as right into the item.Unlike other wheels, rigid wheels can't pivot in a total 360-degree variety. Instead, they can just roll forwards and also in reverse. Inflexible wheels are usually stronger than standard wheels, yet their restricted array of movement makes them a poor option for sure applications. Monroe has a wide range of wheels that cover every application.

Caster wheels are used in shopping carts, office chairs, medical beds, and also product handling equipment. Caster wheel variations differ greatly based upon the application demands and are commonly utilized in a vast array of applications. It is a remarkable wheelchair enabler, with homes such as stamina, corrosion resistance, water resistance, and also climate resistance.

Bullcaster Co.,ltd Things To Know Before You Buy

Hefty products need casters with thicker wheels, some bigger items might require multiple wheels to evenly disperse weight. This area will certainly discuss the production procedures included in making caster wheels.Plasma cutting is a sort of thermal reducing that makes use of an ionized gas to cut the steel. https://www.giantbomb.com/profile/bullcasterco/. This indicates that the procedure makes use of heat to melt the metal rather than mechanically sufficing. It is among one of the most typical approaches for cutting thick metal plates, yet it's likewise useful for sheet steel.

Forks are the arms that hold each side of the wheel axle (casters manufacturer). The forks are made out of steel coil, a more adaptable and also thinner type of steel.

Journalism bends the item into the required shape and also it my website additionally makes a round groove around the opening in the center. The hole is full of steel round bearings that enable the yoke to swivel. A steel retainer is fitted to hold the round bearings in position. The grooves of the steel cap are full of ball bearings also then they place it onto a strike press and also place the yoke on the top.

7 Easy Facts About Bullcaster Co.,ltd Described

After captivating the leading plate to the yoke, put a steel seal over the retainer and also secure it in position with a pneumatic press. The next machining procedure on the manufacturing of wheel wheels is the extrusion of the wheel material. To make the wheels, nylon inserts are required. The inserts are put in an injection molding press, which melt neoprene rubber and infuses it into the mold and mildew.The rubber side soaks up shock, reduces noise, as well as prevents damage to the floor or surface. For larger sized wheels, a various molding press is used to match the called for size. The molding procedure to generate the wheel is the very same. These larger molding press equipments generally make one wheel each time.

The steel guides place the wheel in between the yokes and also put the steel wheel axle. The wheel needs to undertake a series of quality control tests that count the number of revolutions a wheel can stand up to prior to it ultimately damages.

A swivel caster, on the various other hand, might be a much better alternative if there's requirement for even more ability to move. Think about also whether there's demand for swivel locks, if devices is to be relocated a straight line. The capability to relocate something is why wheels are placed on it, yet there's also require to know just how much freedom there remains in that motion.

Little Known Facts About Bullcaster Co.,ltd.

Lots of applications require a stem mounted caster, although this can limit the wheel's weight ability. Sturdy wheels will certainly make use of a plate install to protect the caster and distribute the tons over a better placing area. Understanding the placing preference can aid limit the alternatives when selecting casters from a substantial number.Report this wiki page